You can even utilize common house items to create this early-stage design. Most importantly, collaborate with a product advancement firm that offers specialist guidance throughout the whole procedure. They will ensure you are complying with the right steps at the right time and will be there to address any kind of questions in the process. This consists of a pre-production, high-fidelity prototype and in-depth specifications the producer will certainly need to start automation. Alpha development and beta screening specifically will offer you numerous prototypes to examine. You can consider alpha screening as one of the most basic of all models.

Manufacture Phase Manufacturing Prototyping

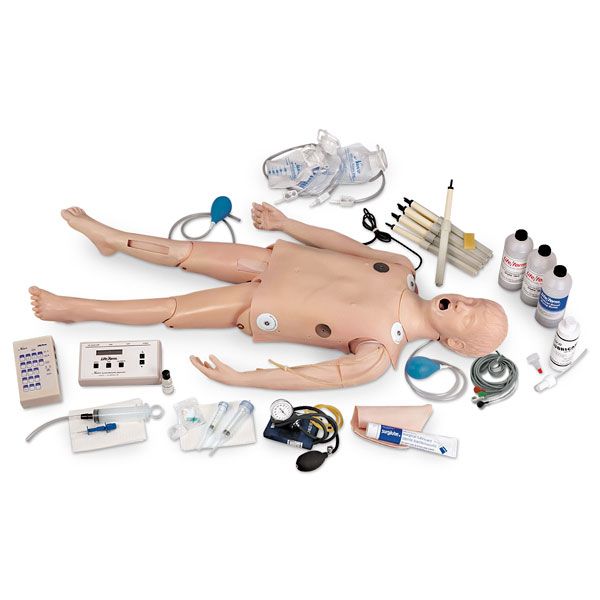

Throughout the alpha testing stage, you will certainly conduct a danger analysis, answering questions such as whether the materials are inexpensive and sustainable. Your goal is to identify any kind of hazards to item growth, your supply chain, and productivity. When you have a brand-new item concept, you need to understand if it is possible prior to you can relocate to the next stage. This evidence of idea phase includes a considerable quantity of study, as well as your initial illustrations. An advancement team or design group is seeking info to identify whether their idea is practically practical and if customers will certainly discover the item appealing and important adequate to buy. When you have a rough sketch of your product, you can training manikins - cpr-depot.ca make use of a software tool to produce a 3D version of your product.

Create A Production-ready Prototype

Models serve as substantial versions so investors can see what the product must look like. When done correctly, they can persuade stakeholders to sustain the item. Models also enable customers and customers to see truth capacity of your item. Through prototyping, item managers can check various materials and manufacturing methods they think would be best for the item.

Wagestream Engineering Spotlight: Jamie Potter, Design Manager

It is produced with the intent of the end product option but might not be created by the last production procedure, Visit this link materials, or tooling. It is completely practical, and the look looks similar to a completed product. Designers verify the form, fit, and feature of the design before investments are made in tooling, equipment, and top quality checks. Idea illustration prototyping is where the product concept satisfies its initial test. It is when you move the item concept onto paper or a computer.

High-fidelity prototypes that closely match the last desired product can be created. User screening usually highlights unpredicted issues with the style and can supply beneficial understandings to enhance the high quality of the product. A pre-production prototype is the last model prior to production takes place.

Environmental tests might also be needed to guarantee the item will certainly operate in its intended setting without extreme deterioration or general environmental deterioration. The job range have to be specified before beginning any type of new product development trip. Normally, the job scope is identified by the client or created with completion individual cpr manikin or end feature in mind.

Swimwear Brand Arena Achieves Faster, More Sustainable Prototyping with Dassault Systèmes' 3DEXPERIENCE Works - Dassault Systèmes

Swimwear Brand Arena Achieves Faster, More Sustainable Prototyping with Dassault Systèmes' 3DEXPERIENCE Works.

Posted: Wed, 14 Feb 2024 08:00:00 GMT [source]

For instance, let's state you're setting up a vehicle rental system and you're aiming to examine its performance. If you are attempting to start a business with a new, exclusive product-- or develop brand-new items for your existing business-- one of the most crucial actions is to develop an item model. The manufacture phase model is the final recognition check before mass production of the product. The initial off-the-line products will certainly be user-tested under real-world applications in the area. Select customers provide comments about the dependability and functional performance of the product. The item assembly procedure is likewise enhanced and examined during this phase with the aid of the QC or quality control standard procedure.

The job extent is usually well-defined, with clear deliverables that help maintain stakeholders lined up and avoid range creep. A distinct scope needs to consist of the appropriate layout requirements, sector laws, efficiency demands, overall item measurements, and setting up needs. Including these essential factors in the scope helps in reducing the danger of having to change the trajectory of the design completely.

Different models of these aids can be created and examined to see what jobs and what doesn't. This procedure will ensure there are less obstacles when increase to major manufacture. Prototyping during the design phase includes particular elements or subassemblies to examine if parts can be put together, devices can operate as expected and can interface correctly with existing devices.

CPR Depot

340 Croft Dr, Tecumseh, ON N8N 2L9, Canada

+15199462222